We are able to offer various pre-treatment services including shot blasting, de-greasing and iron phosphate coating.

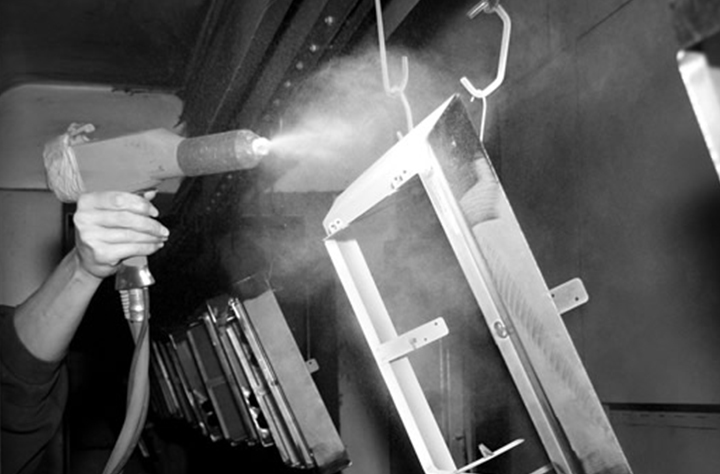

The Phosphating process is a complex chemical one which involves converting the surface layer of metal into a strong, insoluble metal phosphate. Phosphating creates a rust resistant layer and gives a good base for any coating to be applied. It also gives protection against corrosion. Phosphating solutions usually consist of iron or zinc phosphates dissolved in dilute phosphoric acid. As the solution is applied to the product the reaction between the acid and metal creates a metallic phosphate which forms a layer which is metallic in colour.

Phosphating consists of a 3 stage cycle:

Shot-blasting removes any existing paint or rust and ensures a smoother finish when the item is powder coated. We are able to offer a shot-blasting service for small items, and we can sub-let out larger items to another shot-blasting facility so please don’t hesitate to contact us for more information.

T Wash is a form of pre-treatment used for new galvanised steel and should not be used on weathered galvanising. T Wash is a modified Zinc Phosphate solution which contains a small amount of Copper, when the solution is applied a dark grey or black discolouration of the zinc surface will result.